Loading...

217 view(s)

If you’re having issues with low pressure, especially after the pump has been sitting unused for a period of time, then the check ball may be to blame. People often rely on Simpson pump saver and conditioner (88266), which can help with low pressure. Pump saver is meant to be a preventative measure when you are putting the unit into storage, and will not fix the problem if the check ball is already corroded or if there is any debris around it.

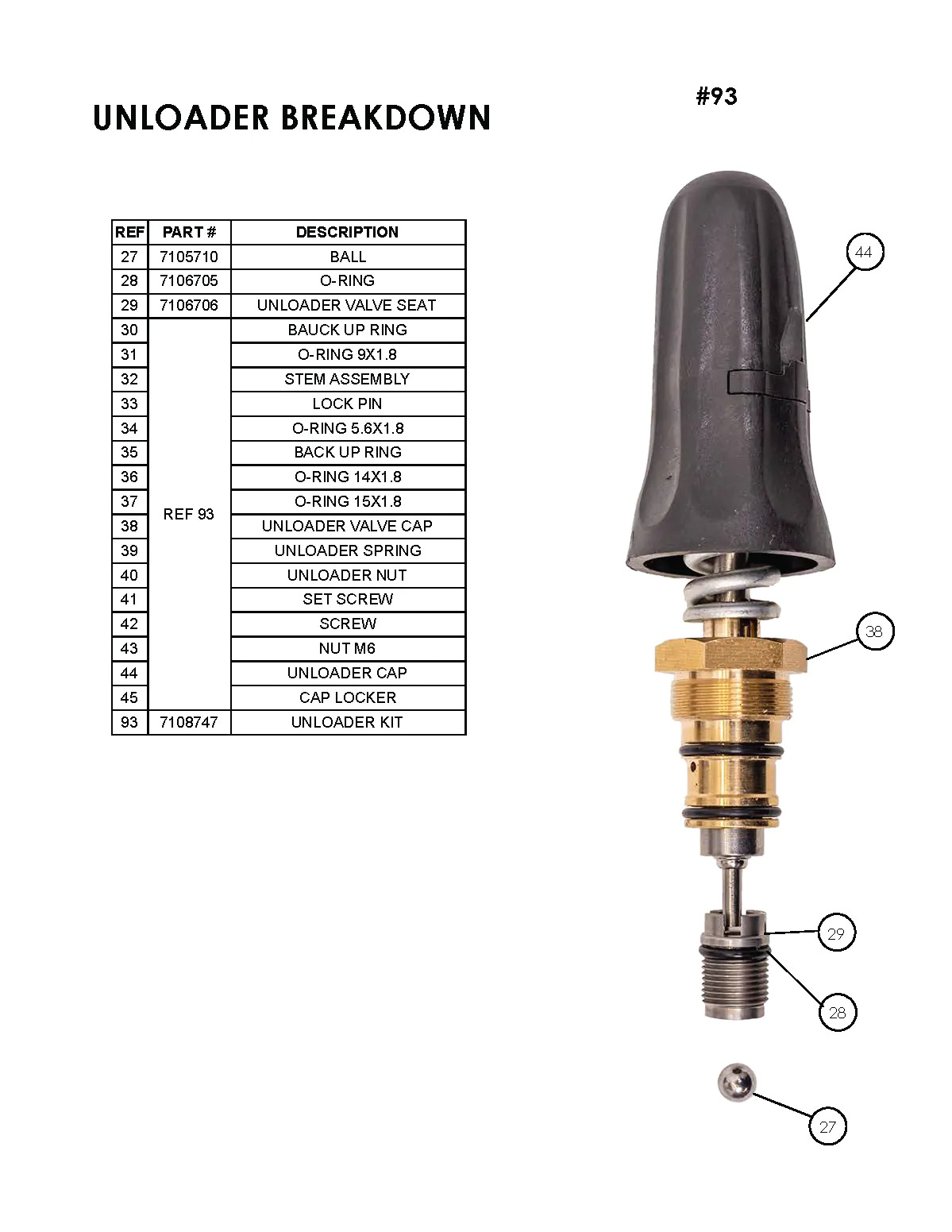

Replacing an unloader with seat:

- In order to remove the unloader from the pump, the brass nut (#38) must be exposed to allow room for a wrench. To do this, turn the black knob (#44) counterclockwise until it stops.

- Remove the complete unloader by turning the unloader’s brass nut (#38) counterclockwise with a 15/16 wrench until the unloader is removed.

- The unloader passage is at the bottom. There is a stainless-steel unloader valve base seat (#29). Underneath the seat is a stainless-steel ball bearing (#27) that sometimes gets stuck and prevents the pump from producing pressure.

- If the ball bearing is not severely corroded into the seat, you can use compressed air to dislodge the ball bearing without removing the seat. Be sure to wear eye and hand protection for this step.

- If the removal of the seat is required, you will need to turn the seat (#29) counterclockwise with a tool that has a very tight 3MM fit within the unloader seat.

- Verify that the plunger will push in and out easily without much effort by pressing on it it gently. If it is stuck, tap it gently to free it up and then lubricate it with a penetrating oil. If the plunger is not stuck, the next step is to check and see if the steel ball is stuck.

- You will need to remove this unloader seat (#29) from the brass head and remove the ball bearing (#27) to check for corrosion or debris that could be causing the ball bearing to get stuck in the unloader seat.

- There is no tool for removing a seat, so we made one from a ½ inch hexagon shaft chisel by grinding down the end to the 3MM required. We used this chisel so we could get a wrench on the tool to remove the seat from the pump.

- Clean out any debris or corrosion from the unloader valve passage before starting the reassembly process.

- Install the stainless-steel ball bearing (#27) base seat and O-ring (#28) and (#29) back into the brass manifold by applying a thin coat of grease on the O-ring and then torque the unloader seat to 10 FT-LB.

- Reinstall the complete unloader assembly (#93) by applying a thin coat of grease on the O-rings and then torque the unloader securely to 15 FT-LB.

These instructions are for unloaders used with 7108752 manifolds. If you need instructions for the 7108746 manifold, refer to the pdf we have attached here.