2025 © Allparts Equipment & Accessories. All Rights Reserved.

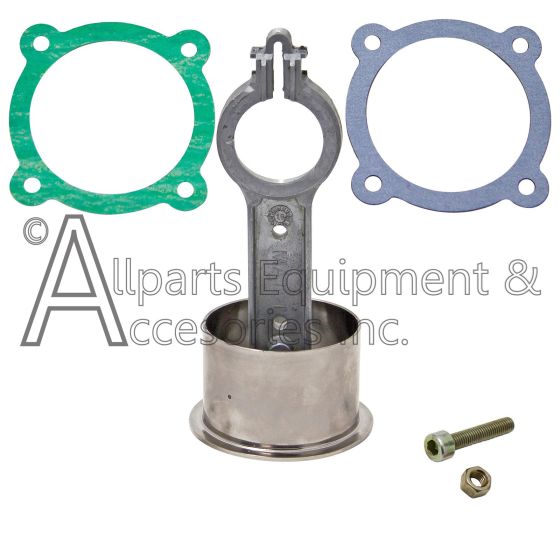

5140240-52 Piston Kit Single Cylinder Oil Free Pumps

5140240-52 Piston Kits include the Connecting Rod, Piston Ring, Cylinder Sleeve and Gaskets for the Oil Free air compressor pump.

The 5140240-52 Piston and Cylinder Kit was used on air compressors manufactured by MAT Industries and sold as Black and Decker, Husky, Porter Cable, Sears Craftsman and others..

- Inside Diameter: 63mm

- Outside Diameter: 66mm

- Outside Shoulder: 78mm

- Total Height: 44.85mm

The Piston Kit approximate cylinder dimensions are as follows:

Some model numbers include:

- Porter Cable:

- PXCMF226VW

- F2226VWD

585-819 / 585819

- Sears Craftsman:

- 921167500 / 921.167500

- 921166420 / 921.166420

- 921166430 / 921.166430

- 921164710 / 921.164710

Service Note:

The correct color codes spacer gasket

must be used when completing the repair of your oil free air compressor pump

for proper function and to prevent damage from occurring.

These specific colored “spacers gaskets” are

used to control the proper clearance between the connecting rod cap and the

valve plate in the compressor pump assembly.

It some cases BOTH spacer gaskets may need to be used.

If your original oil free compressor pump previously had a single-colored spacer

in place, then you will need to use the same color spacer from

this service kit.

Each kit comes with two colored spacer gaskets with the following specifications.

Green Spacer Gasket approximately .012 - 0.15” in thickness.

Grey Spacer Gasket approximately .035 - 0.39” in thickness.

These colored gasket spacers when

use is required are

intended to be placed between the top of the pump casting and the cylinder sleeve.

The lip of the cylinder must sit on top of the colored spacer gasket to create the

proper clearance.

*Important Note*

If

the incorrect spacer gasket is used or if you place them on top of the

cylinder sleeve instead of under it, the con-rod cap could possible strike the bottom

of the valve

plate assembly and cause server damage.

During reassembly it is always recommended to “Rotate

the pump by hand” before the final tightening

of the compressor head.

This will insure proper piston rod to valve plate clearance has been achieved and

that there is no binding of any reassembled components prior to the air

compressor being plugged in and turning at the high RPM’s incurred and thus preventing

any permanent damage.

Service Note: The correct color codes spacer gasket must be used when completing the repair of your oil free air compressor pump for proper function and to prevent damage from occurring. These specific colored “spacers gaskets” are used to control the proper clearance between the connecting rod cap and the valve plate in the compressor pump assembly. It some cases BOTH spacer gaskets may need to be used. If your original oil free compressor pump previously had a single-colored spacer in place, then you will need to use the same color spacer from this service kit. Each kit comes with two colored spacer gaskets with the following specifications. Green Spacer Gasket approximately .012 - 0.15” in thickness. Grey Spacer Gasket approximately .035 - 0.39” in thickness. These colored gasket spacers when use is required are intended to be placed between the top of the pump casting and the cylinder sleeve. The lip of the cylinder must sit on top of the colored spacer gasket to create the proper clearance. *Important Note* If the incorrect spacer gasket is used or if you place them on top of the cylinder sleeve instead of under it, the con-rod cap could possibly strike the bottom of the valve plate assembly and cause server damage. During reassembly it is always recommended to “Rotate the pump by hand” before the final tightening of the compressor head. This will insure proper piston rod to valve plate clearance has been achieved and that there is no binding of any reassembled components prior to the air compressor being plugged in and turning at the high RPM’s incurred and thus preventing any permanent damage.