2025 © Allparts Equipment & Accessories. All Rights Reserved.

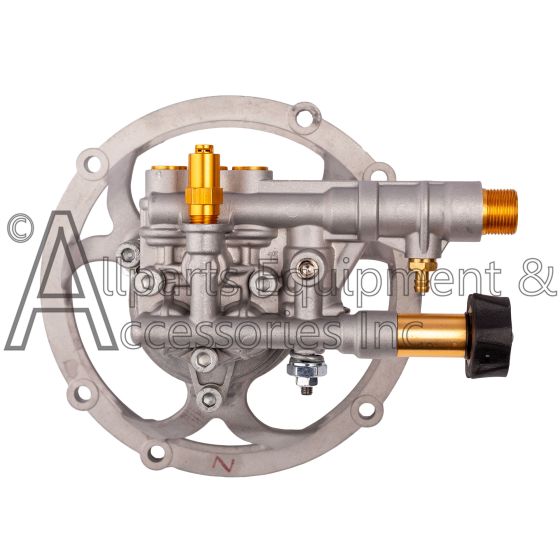

7107969 Pump Kit 2700 PSI max 2.5 GPM Round Mounting Flange fits MSVK2723

The 7107969 Service Pump from OEM Technologies pump is an oil-filled Direct-Drive Axial Cam pump used in various pressure washers using a 22MM High Pressure Hose connection.

This OEM Technologies industry-leading vertical mounting pump with a 7/8 shaft and has a universal round base mounting flange allowing multiple-direction mounting and is rated for 2700 PSI at a flow rate of 2.5 GPM Max PSI

The 7107969 pump utilizes PowerBoost technology to generate higher pressure at the spray nozzle, ensuring that pressure isn't lost as water travels through the power washer system.

Features of the OEM Axial Cam Pump from OEM Technologies

- High-pressure pump rated for 2700 PSI @ 2.5 GPM

- Multi-point round base vertical mounting flange

- AAA PowerBoost technology keeps the water pressure strong

- Included thermal relief valve protects against overheating

- Corrosion-protected aluminum crankcase reduces wear and tear from regular use

- A Sealed and oil-filled crankcase ready to bolt on and Start pressure washing

- 7/8 Hollow shaft that fits most vertical shaft engines

- Includes siphon tube with filter, mounting bolts, and a shaft key

The pressure washer pump is rated for a maximum pressure of 2700 PSI at a flow rate of 2.5 gallons-per-minute (GPM.)

This OEM tch Series pump utilizes a dual axial cam bearing for better wear, friction resistance, and longer-lasting performance in tough cleaning environments.

An integrated stainless steel unloader features an industry-leading easy-start system.

7107969 OEM Solutions Pump Specifications:

Additional Notes & Service Information

This Pressure Washer pump kit is not designed for gravity-fed systems, and an on-demand water pump is always recommended to consistently supply water to the pump at 20-60 PSI of inlet pressure.

Service Note:

The "Burst Pressure" of a pressure washer pump is the highest pressure the pump produces when in a static position and when the trigger is first squeezed, giving the initial burst of pressure and does not reflect the actual operating pressure.

The accurate operating PSI of any pump would be determined by the engine’s horsepower and the size of the nozzle being used at the end of the wand, which restricts water flow and causes back pressure.

Adjusting factors such as engine RPMs, nozzle size, or engine horsepower can allow a single pump to be rated at various GPM and maximum PSI levels.